Cutting with laser, water jet, milling cutter

Material and application specific processes

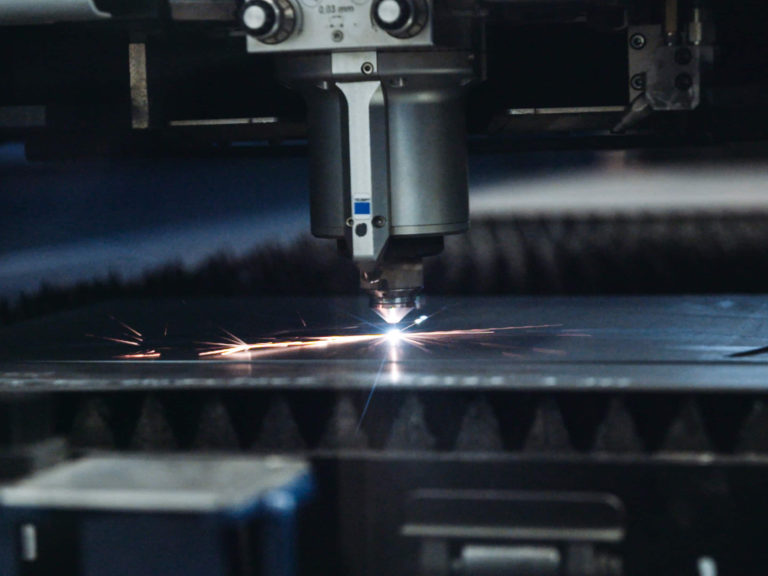

Laser cutting

Stahlkontor has seven powerful CO2 laser systems, including a 3D laser processing system with 7,000 watts of power for XXL formats. Some of the systems are equipped with 3D processing heads so that, in addition to 90° cuts (2D cutting), components with angled edges/bevels (2.5D cutting) or processing on spatially shaped components (3D cutting) can be performed.

- Material insert sizes up to 4,500 x 12,000 mm

- Material thicknesses up to 25 mm in laserable material grades (25 mm mild steel, 20 mm stainless steel oxide-free)

Waterjet cutting

As a “cold” cutting process, waterjet cutting is particularly suitable for processing heat-sensitive materials. Where conventional cutting processes reach their limits, it often offers a technically and economically optimal alternative.

Stahlkontor has seven different high-pressure waterjet cutting systems, both for pure water and abrasive waterjet cutting and pressures up to 6200 bar. Depending on the component geometry, up to four cutting heads can be operated in parallel. Additional axes in the cutting head allow 90° cuts (2D machining), bevel cuts (2.5D) and spatial machining (3D) to be realized.

Material input sizes

- Material insert sizes up to 5,000 x 12,000 mm and special sizes beyond that

- Material thicknesses up to 200 mm, in individual cases even greater

Single sheet weight up to 10 t

Our 5-axis, CNC-controlled gantry waterjet cutting system is specially designed for 3D cutting of large, spatially shaped components. The max. working area is approx. 1,500 x 5,000 x 6,000 mm.