Customized welding

Conventional, Innovative and Exclusive Technologies

Conventional welding technology

- MAG/MIG and TIG welding processes (for applications in the field of high-strength fine-grained structural steels, structural steels, stainless steels and aluminum)

- Orbital MAG/MIG process

- Stud welding with tip and drawn arc ignition

CO2 laser beam welding

- Profile welding up to 12 m length

- Butt welding (linear) of oversized blanks

- Butt welding (linear/non-linear) of formed blanks (Tailored Welded Blank/TWB)

- Construction welding with the laser beam (planar/spatial)

Laser hybrid welding

Laser hybrid welding is a process combination of the MAG/MIG process and CO2 laser beam welding. This plant-integrated technology combines the advantages of both welding processes and enables large welding depths at high welding speeds, resulting in low thermal stress on the base material. The process is used in particular for the production of laser-welded profiles.

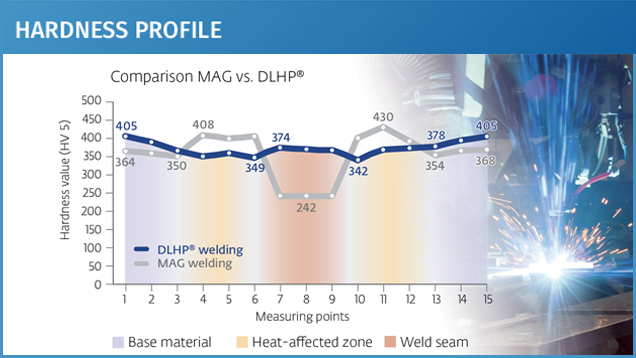

Double Laser Hybrid Process (DLHP®)

The Double Laser Hybrid Process (DLHP®) combines simultaneous laser/MAG welding with a special inductive heat treatment of the steel. This demonstrably reduces the risks of cracking and fracture under load in the weld area. The process developed and patented by Stahlkontor is suitable for the safe, faster and more economical production of parts and components for armored vehicles of all types, rail vehicles, door systems and facade elements made of high-strength steels. Comparative impact and sprue tests have already been successfully completed at Wehrtechnische Dienstelle 91.

Diverse certifications and approvals

Stahlkontor is a certified welding company in accordance with DIN EN ISO 3834-2 for defense technology, rail vehicles, plant and mechanical engineering and holds approvals from the German Federal Office of Defense Technology in accordance with DIN 2303-Q2/Q3 BK1 (welding of defense technology products), TL 2350-0003 (armored casings), certification in accordance with DIN EN 15085 -2 CL1 (welding of rail vehicles and parts) and certification in accordance with EN 1090 -1 to -3 EXC 3 (welding certification for designs of steel and aluminum supporting structures).