Machining processing

From prefabrication to finished part

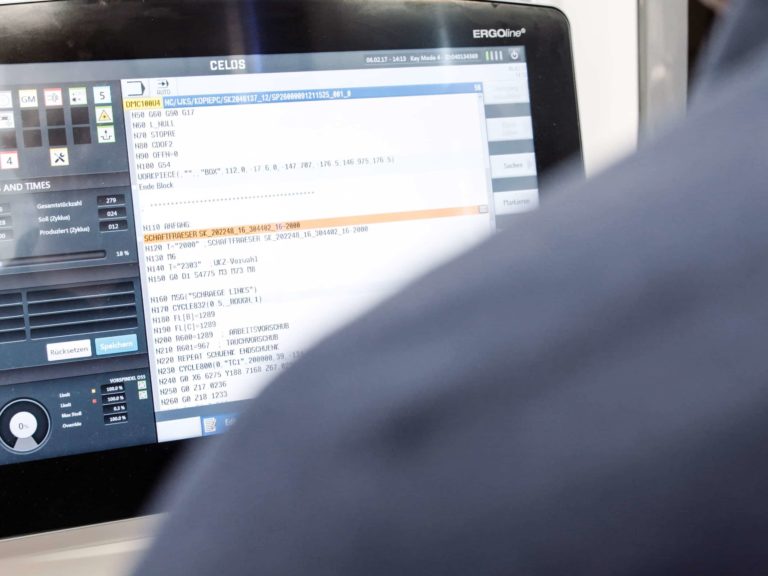

For some years now, Stahlkontor has also been involved in the manufacture of geometrically demanding milled components. Our particular strength here lies in the machining of high-strength materials such as titanium and armored steel. However, we also master the machining of conventional materials. With our modern 5-axis and 3-axis machinery, we face up to highly demanding tasks and produce precise components for our customers in a wide range of batch sizes.

The range of machining services offered by Stahlkontor extends from the simple machining of welding bevels to the finishing of technically demanding, geometrically complex structural parts and assemblies made of high-strength metallic materials.

Technical possibilities

Together with our network partners, we are proud to be able to offer our customers exceptional technical possibilities for machining production.

For the processing of our customers orders we have more than ten different machines with different performance characteristics at our disposal:

- 5-axis, 3+1-axis and 3+2 axis machining

- Machining space of maximum 5,000 x 1,250 x 1,250 mm

- Possible pre-material weight up to 3,000 Kg

Equipping the systems with heavy-duty cutting spindles with particularly high drive power to handle the heaviest tasks.

Network for the expansion of technical possibilities

For machining operations, we use both our own machinery and the capacities of our permanent network partners. The machine facilities available in the network enable the economical and flexible production of single and mass-produced parts as well as the sophisticated machining of complex large components.